Contents:

- Intro

- Common Solar Panel Problems and Potential Issues

- Solutions: Choose Reliable Solar Panels

- Conclusion

Introduction

In the present era, where the emphasis on renewable energy is paramount, solar panels have become a focal point of the clean and sustainable energy landscape, drawing increased attention. However, the rapid advancement of solar technology has brought to light certain issues and challenges associated with solar panels. To ensure the smooth operation and long-term effectiveness of solar energy systems, it is crucial to closely examine these challenges and seek reliable solutions. This article aims to explore common problems related to solar panels and provide guidance on choosing dependable solar panels to optimize the efficiency of solar energy systems.

Common Solar Panel Problems and Potential Issues

Hot Spot Effect

Solar cells are meticulously designed to generate electric current when exposed to sunlight. The hot spot effect, characterized by localized high-temperature areas on the solar panel surface, stems from uneven current distribution or other contributing factors. As this current flows through interconnected strings of solar cells within panels, the inherent resistance in the cells converts some of the current into heat losses. Imperfections in solar cells, such as microcracks, inadequately soldered joints, or mismatches, increase resistance, significantly diminishing the overall efficiency of the solar panel and eventually leading to the formation of hot spots. Over time, the prolonged existence of hot spots can result in burn marks, compromising the integrity of both the solar cells and backsheets. If not addressed, these conditions may escalate, posing a potential risk of fires.

Microcracks and Snail Trails

Microcracks and Snail Trails pose challenges in the realm of solar panels, arising from the advent of ultra-thin solar cells, approximately 170 μm thick—twice the diameter of a human hair. While this technological progression enhances efficiency, it renders the solar cells brittle and prone to cracking upon forceful impact, resulting in the formation of microscopic fractures or snail-like patterns on the panel surface. Microcracks, stemming from manufacturing stresses or external impacts, and "snail trail" imperfections, observable without magnification as slender, dark lines in a spiral configuration, adversely affect both optical and electrical performance. These structural issues hinder the conduction of electric current in compromised cells, leading to reduced energy production and the potential emergence of hot spots. Addressing these vulnerabilities is imperative for ensuring the sustained functionality and durability of solar panels.

Solar Panel Breakage

Solar panels face the risk of physical impacts during transportation and installation, exposing them to potential damage. Additionally, they prove highly vulnerable to thermal stress induced by weather fluctuations, such as extreme heat or cold, resulting in substantial temperature variations. This thermal expansion and contraction exert pressure on the structural integrity of crucial components, including glass, solar cells, and frames, potentially leading to damage and negatively impacting overall panel performance. In instances where external forces are forceful enough to break the glass and damage the internal cells, the consequences become more severe. Direct harm to solar cells has a cascading effect on panel performance and efficiency. Cracks or breakages can disrupt the even distribution of current, diminishing overall energy conversion efficiency. Such damage also gives rise to hotspots and performance degradation, compromising the reliability and lifespan of the entire solar energy system. Thus, safeguarding the integrity of solar cells becomes paramount for ensuring the sustained operation of the system over the long term.

Performance Degradation

Prolonged usage introduces a range of factors contributing to performance degradation in solar panels, encompassing phenomena such as Light-Induced Degradation (LID), Light and Elevated Temperature-Induced Degradation (LeTID), and Potential-Induced Degradation (PID). LID manifests as reduced efficiency in solar cells exposed to sunlight, while LeTID involves degradation occurring simultaneously under light and elevated temperature conditions. PID, on the other hand, denotes a decline in performance induced by potential-related stresses. The collective impact of these degradation mechanisms underscores the significance of actively monitoring and mitigating factors that influence the long-term performance of solar panels, ensuring sustained optimal energy production over time. For an in-depth exploration of solar panel degradation, you can refer to Maysun Solar's blog post on the subject by clicking the button below.

Backsheet Tearing

The occurrence of backsheets tearing, particularly during the installation process, presents a potential hazard to the waterproof capabilities of solar panels. Given the daily exposure to intense UV radiation and temperature fluctuations, solar panels face environmental stressors that can compromise their structural integrity. The presence of cracked backsheets signals suboptimal component selection, potentially allowing water vapor to infiltrate the module laminate and cause harm to the solar cells. This emphasizes the critical importance of careful component choices to mitigate risks related to environmental stressors and uphold the durability and efficacy of solar energy systems. Regular inspections and proactive measures are imperative to address these issues, ensuring the ongoing efficiency of solar energy systems.

Solutions: Choose Reliable Solar Panels

To address the prevalent challenges associated with solar panels, suppliers have introduced advanced technologies, exemplified by IBC solar panels and HJT solar panels, designed to effectively circumvent common issues. Examining the advantages of these innovative solutions sheds light on their efficacy in resolving key problems.

IBC Solar Panels

No hot spots

IBC solar cells incorporate the unique All Back Contact technology, where rear-side positive and negative metal electrodes ensure a consistent flow, even in shaded conditions. This design minimizes resistance on the front side, effectively mitigating potential damage from hot spots. By eliminating front-side resistance, this technology not only reduces the risk of hot spot formation but also minimizes operational risks for entire solar power plants.

High reliability

IBC solar panels offer substantial improvements in reliability. By eliminating the conventional Z-soldering process for cell welding strips, IBC solar panels reduce the number of solder joints by 80% compared to TOPCon. This modification eliminates the risk of false soldering or over-soldering, resulting in enhanced reliability and stability for IBC solar panels.

Higher weather resistance

IBC solar panels exhibit high weather resistance due to the sophisticated All Back Contact design, preventing tension-related damage and detachment caused by thermal expansion and contraction of the front welding strip during significant temperature stress. This design minimizes the impact of thermal stress, reducing structural pressures on components like glass and solar cells, ensuring stable generation performance and maintaining panel integrity.

Anti-LID effect

An notable advantage of IBC solar panels is their anti-LID effect. Exceptional moisture resistance significantly mitigates panel degradation caused by environmental stressors, including Light Induced Degradation (LID), Light and Elevated Temperature Induced Degradation (LeTID), and UV Induced Degradation (UVID). This enhanced moisture resistance enables IBC solar panels to withstand prolonged exposure to light, elevated temperatures, and ultraviolet radiation, minimizing degradation and ensuring prolonged efficiency and stability.

Sturdy and waterproof backsheet

IBC solar panels feature a backsheet coated with a PVF Tedlar film, enhancing waterproof performance. This design ensures superior water resistance, contributing to the overall durability and reliability of the solar panels. The use of PVF Tedlar membrane as a backsheet enhances protection against moisture ingress, extending the lifespan of the panels.

Maysun Solar’s IBC solar panels seamlessly integrate the benefits of IBC solar cells, offering high efficiency, aesthetic appeal, and an extended lifespan. Choosing Maysun Solar’s IBC solar panels is a smart decision for those aiming to maximize efficiency and overall performance. The image below illustrates Maysun Solar's IBC black frame solar panels installed by their Italian customer. For further details, click the button below!

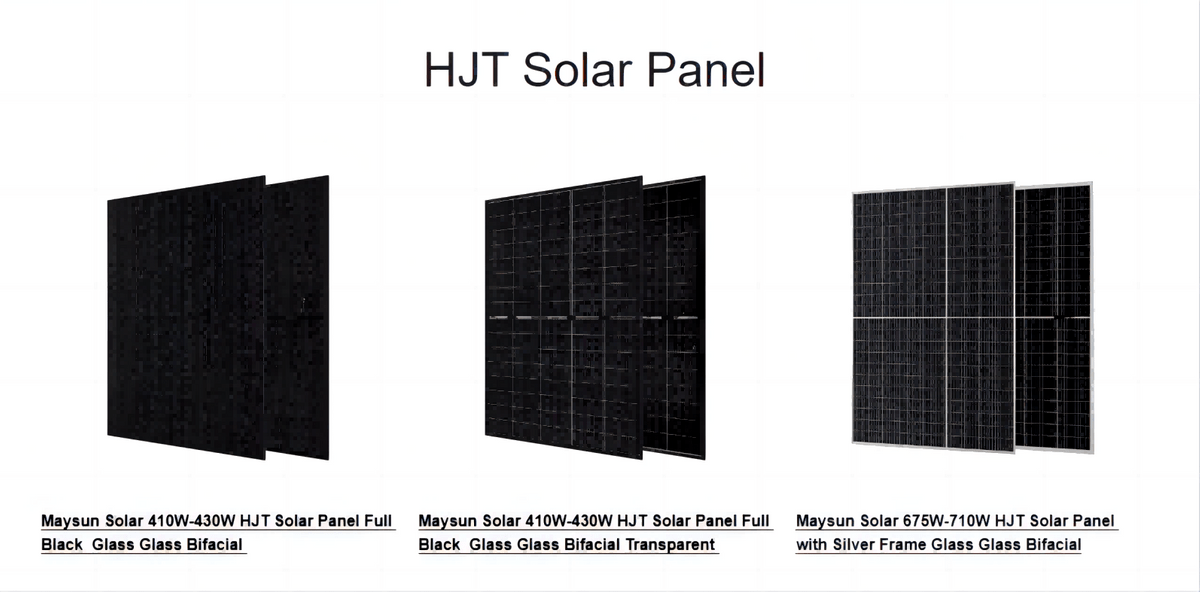

HJT Solar Panels

Low Degradation

HJT cells eliminate the possibility of electronic effects on their surface, ensuring no Light Induced Degradation (LID) or Light and Elevated Temperature-Induced Degradation (LeTID) effects. The initial year's power degradation for HJT solar panels is only 1%, with an average annual degradation of 0.35% thereafter. Over a 30-year lifespan, the power generation capacity of heterojunction solar panels will not decay by more than 11.5%, resulting in a consistently stable power generation throughout their lifecycle.

Stronger PV Material

Backed by a robust 30-year product warranty, HJT solar panels provide customers with long-term assurance of durability and performance. This extended guarantee is attributed to the utilization of weather-resistant, corrosion-resistant, and wear-resistant double-sided semi-tempered glass, combined with POE encapsulation technology. The double-sided semi-tempered glass not only enhances the HJT solar panel's resilience against adverse weather conditions but also contributes to its resistance against corrosion and wear over time, reducing the likelihood of glass breakage. The POE encapsulation further ensures the integrity of the solar panel, providing a comprehensive safeguard that extends both its longevity and performance. These advanced materials and encapsulation technologies make HJT solar panels a reliable choice for sustainable and enduring solar energy solutions.

Effective Reduction of Microcracks

Heterojunction (HJT) technology effectively mitigates microcrack formation through No-Cut solar cells and a low-temperature manufacturing process. HJT solar cells feature an extensive and refined busbar design, contributing to improved stress distribution on the cell surface. This design minimizes stresses caused by thermal expansion, optimizes current distribution, and reduces the risk of microcrack formation and busbar breakage. These design adjustments significantly enhance the performance and reliability of HJT solar panels, offering an innovative solution for improved stability and durability in photovoltaic systems.

Low Temperature Coefficient

In comparison to PERC and TOPCon solar cells, Heterojunction (HJT) solar cells exhibit a lower temperature coefficient (-0.24%/°C), ensuring a more stable power generation performance in high-temperature environments and reduced power losses. This characteristic enhances the overall efficiency and reliability of HJT solar cells, making them particularly advantageous for applications where temperature variations play a significant role.

Discover innovation in renewable energy with Maysun Solar’s Heterojunction (HJT) solar panels. Utilizing cutting-edge Heterojunction Technology, these panels offer exceptional efficiency with a consistent, high voltage output in low-light conditions. Featuring a low-temperature coefficient (-0.243%/°C), they ensure sustained performance in hotter climates for effective energy generation. With an impressive 95% bifacial rate, Maysun Solar’s HJT panels optimize solar energy absorption, enhancing the energy yield of your photovoltaic system. Click below for a deeper insight into the capabilities of HJT solar panels and embrace cleaner, more efficient energy solutions!

Conclusion

In conclusion, addressing common solar panel issues such as the hot spot effect, breakage, performance degradation, and backsheet tearing is crucial for minimizing maintenance and ensuring trouble-free operation. Opting for reliable, high-quality solar panels not only mitigates these problems but also reduces the overall Levelized Cost of Electricity (LCOE), leading to greater economic benefits. LCOE, representing the average cost to generate one unit of electricity, incorporates total costs, investments, operational and maintenance expenses, and electricity output. A lower LCOE signifies reduced overall costs and enhanced efficiency in electricity generation. Explore the article by clicking the button below to delve deeper into the concept of LCOE and its implications.

Maysun Solar has been dedicated to manufacturing top-tier photovoltaic modules since 2008. Explore our extensive range of solar panels, including full black, black frame, silver, and glass-glass options, all incorporating cutting-edge technologies such as half-cut, MBB, IBC, HJT, and Shingled. These panels are designed for superior performance and boast stylish aesthetics that seamlessly integrate with any architectural setting. Maysun Solar has successfully established offices, warehouses, and enduring partnerships with skilled installers across numerous countries. For the latest module quotations or any inquiries related to photovoltaics, please feel free to reach out. We are eager to assist you in harnessing the power of solar energy.

You may also read: